Procotex Corporation and its daughter company Apply Carbon (FR) is a leading manufacturer of sustainable technical fibres for reinforcing compounds, to make compounds more electrical conductive or to increase their friction and wear resistance. On the other side it helps to reduce the weight in comparison with glass fibre reinforced compounds.

Other fibres such as Polypropylene and Polyamide waste fibres are collected and rebaled to supply the regranulation industry giving new life to plastics which might otherwise be treated as waste. PP fibres are blended with natural fibres in non-wovens to thermobonded both together into composites.

Fibres

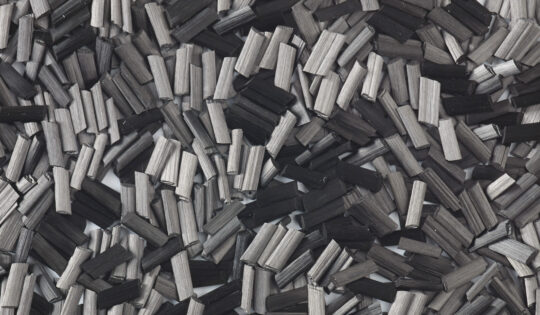

- Carbon: fibre reinforcing and electric conducting thermoplastics

Data for a PA66 compound with a recycled carbon fibre content as low as 10% shows property levels typical for a 30% glass-filled material but with static-dissipative behaviour. Further increasing the carbon fibre content to 30% results in a 150% higher specific stiffness and a 65% higher specific strength than an equivalent glass-filled compound, but with conductive or EMI-shielding behaviour. Procotex is now also developing pellets with a carbon fibre length of 1-3mm to offer even higher conductivity and improved reinforcing capacity along with accurate, dust-free handling and high filler dispersibility. With the automotive industry in mind, Procotex also plans to offer carbon fibre products with a sizing developed specifically for a polypropylene matrix.

Learn more

- Aramid: fibre reinforcing thermoplastics and elastomers, increase of wear resistance and tribology.

Procotex Corporation, and its daughter company Apply Carbon (FR), is a leading manufacturer of sustainable para-aramid fibres for the compounding industry. The latest development are the sustainable recycled para-aramid fibres put in a fiber ball so they can be easily and accurately dosed into the extruder. Because of the length of 1mm, the compounders are encountering less shearing and higher production output in their extruders in comparison with 6mm fibres.

Learn more

- PP:

We supply post producer polypropylene waste fibres from the local carpet and fibre producers towards the regranulation industry giving new life to plastics which might otherwise be treated as waste. PP fibres functioning also as a thermobonding binder with natural or other fibres in composites.

Learn more

- PA:

We supply post producer polyamide waste fibres (PA6-PA6.6) from the local carpet and fibre producers towards the regranulation industry giving new life to plastics which might otherwise be treated as waste. PA fibres can withstand higher temperatures than PP fibres making it ideal for prototyping and manufacturing components that will be subject to resistance.

Learn more

- Natural fibres: fibres to reinforce thermoplastics and compounds

The automobile industry has discovered the advantages to be gained from natural fibers and the natural-fiber composites (NFC) made through the combination of natural fibers (such as flax, sisal, hemp, kenaf, or jute) with different polymers such as: polypropylene (PP), polyethylene (PE), and poly(vinylchloride) (PVC).

Learn more

English

English